Heat pumps are an energy-efficient, low-carbon alternative to traditional heating systems.

By harnessing renewable heat from the ground, air, or water, you can achieve comfortable indoor temperatures at a lower running cost compared to many conventional boilers. The exact savings depend on several factors, including the type of heat pump, the fuel source you’re replacing, the age of your old boiler, and the quality of your existing heating distribution system.

Heat Pump Benefits

Although heat pumps use electricity, the running cost is sometimes significantly lower compared to traditional alternatives. The potential savings depend on several factors such as replaced fuel, age of the replaced boiler, type of heat pump, and quality of the heating distribution system.

The team at Better Planet are experienced engineers who will be able to help you find the best solution for your property.

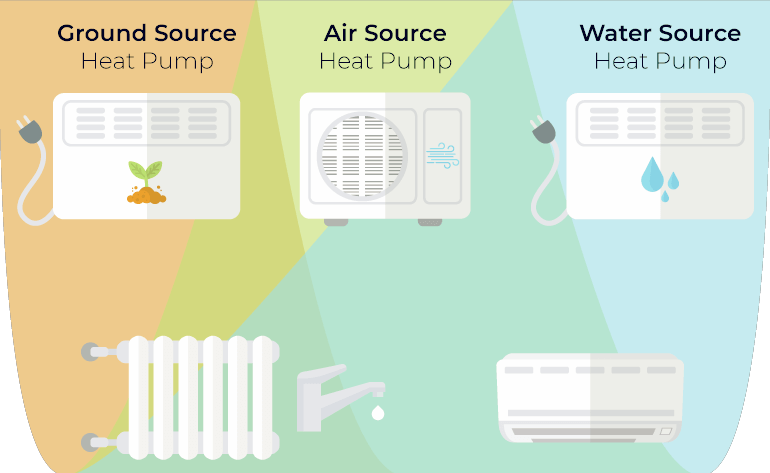

Our Full Range of Heat Pumps

Ground Source Heat Pumps

Ground Source Heat Pumps draw energy from the stable temperatures beneath the Earth’s surface. A series of either horizontal loops or vertical boreholes—buried at a safe depth—collects thermal energy and delivers it to a heat pump unit. The captured energy is then used to provide both space heating and domestic hot water, offering consistent warmth and remarkable energy savings throughout the year.

Air Source Heat Pumps

Air Source Heat Pumps extract renewable heat from the outside air. The main unit, typically placed outdoors adjacent to the property, transfers thermal energy to your home’s heating system. Indoors, the setup often includes a hot water cylinder, buffer tank, and expansion vessels. This versatile and space-efficient solution can significantly reduce energy bills while cutting carbon emissions.

Water Source Heat Pumps

Water Source Heat Pumps utilise thermal energy from ponds, lakes, rivers, or moats. The external pipework—either arranged as “pond mats” or a bespoke configuration—submerges in water to draw heat into the home. Inside, the heat pump unit operates much like a ground source system, providing effective heating and hot water with exceptional efficiency.

Exhaust Air Heat Pumps

Exhaust Air Heat Pumps recycle energy by collecting warmth from the air that would otherwise be ventilated out of kitchens and bathrooms. Integrated ductwork channels this conditioned air through the heat pump, which includes a built-in hot water cylinder. This compact and eco-friendly system is perfect for tightly-sealed modern properties and multi-unit developments.